Using imported safety type high condition weighing sensor, fully sealed, do not recognize steel tree material, fully suitable for coal mine underground high gas, high dust, wet and other harsh environment.

1.Product parameter

Using imported safety type high condition weighing sensor, fully sealed, do not recognize steel tree material, fully suitable for coal mine underground high gas, high dust, wet and other harsh environment.

Using double support, four support and other multi-roller weighing frame, with moisture-proof, seismic, automatic tracking, correction belt deviation and other functions. The door weighing sensor has high sensitivity, stable performance and better accuracy than 0.1%.

2.Electronic belt scale measuring system main functions

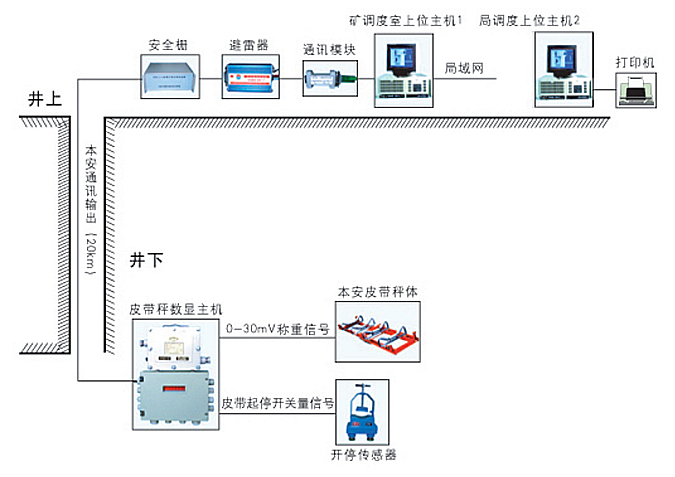

Remote control function, in the ground control room for downhole belt scale output detection, parameter setting, scale and other operations, without opening the explosion-proof shell in the downhole instrument, illegal operation.

An independent intelligent computer has been added to the downhole weighing body in a breakthrough, so that the signals of multiple weighing bodies only need a pair of telephone lines for data transmission, without any converter in the middle, and the control can reach 35KM, ensuring the authenticity of data transmission.

The intelligent computer of the downhole weighing body also has the function of line breaking measurement and protection, to ensure that in the case of power failure or communication interruption of the host system, each weighing part of the weighing body has its own system, independent calculation, memory of the output during the power failure period, after the host system or communication recovery, the data will be transmitted to the host computer, automatic accumulation.

Ground industrial control for PC Windows2000 system development, industrial configuration software programming, menu options, simple operation. The main screen shows the name of the equipment, belt operation, flow, load, instantaneous flow chart, running time of the belt conveyor, etc.

Data query function includes: shift cumulative amount, monthly cumulative amount, total cumulative amount, traffic history curve, historical record query, etc.

With fault self-diagnosis, alarm function, communication fault, sensor, scale body fault self-diagnosis, real-time fault alarm at a glance.

With remote network browsing function: mine leaders sit in the office, remote browsing production status, remote control command.