The ICS series electronic belt scale is ideal for continuous measurement of bulk materials in belt conveyer systems. It has the advantages of simple structure, accurate measurement, convenient operation, small maintenance, easy to communicate with the host computer and so on. It is widely used in electric power, metallurgy, coal, chemical, building materials, port and other industries.

1. Product details

The ICS series electronic belt scale is ideal for continuous measurement of bulk materials in belt conveyer systems. It has the advantages of simple structure, accurate measurement, convenient operation, small maintenance, easy to communicate with the host computer and so on. It is widely used in electric power, metallurgy, coal, chemical, building materials, port and other industries.

2.Adaptability

General environment and acid, alkali, salt and other corrosive environment

Common belt conveyor, skirt belt conveyor, hanging belt machine and air cushion belt conveyor

Belt machine Angle :0°~18

Belt bandwidth: 400~2200mm

Belt running speed :0.01~4.0m /s

Belt conveyor inlet and outlet center distance >1.2m

3.Working principle

When the material passes through, the weight of the material on the metering section acts on the weighing sensor, producing A MV signal proportional to the belt load, while the speed sensor provides a pulse signal proportional to the belt speed. The two signals enter the weighing instrument at the same time, and the two signals are amplified, filtered, converted into A /D and sent to the CPU for integral calculation. Then the instantaneous flow rate and accumulated weight of the material are displayed on the display panel.

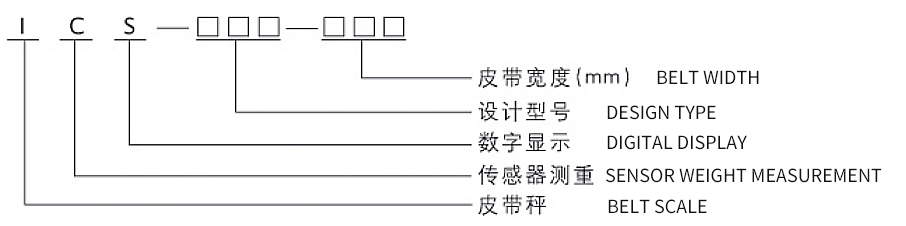

4.Product model and meaning

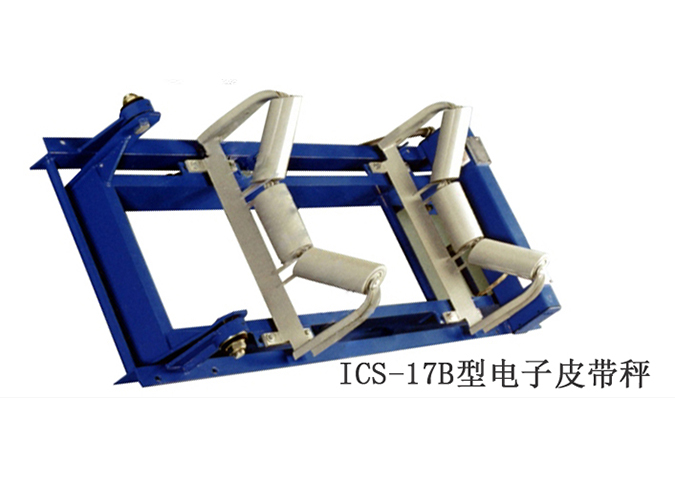

5.Structural feature

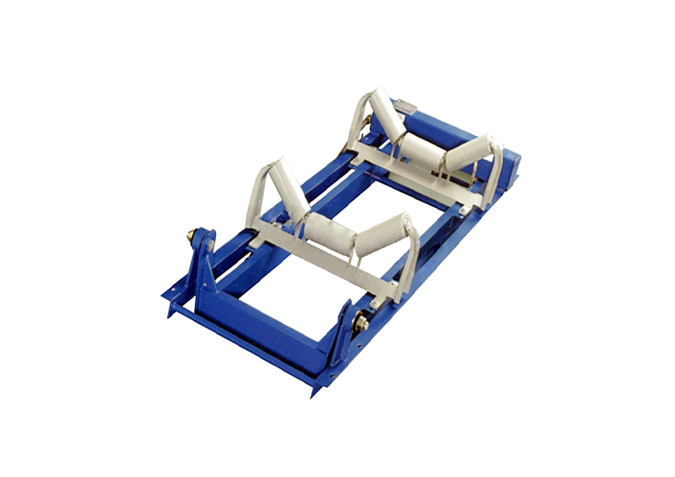

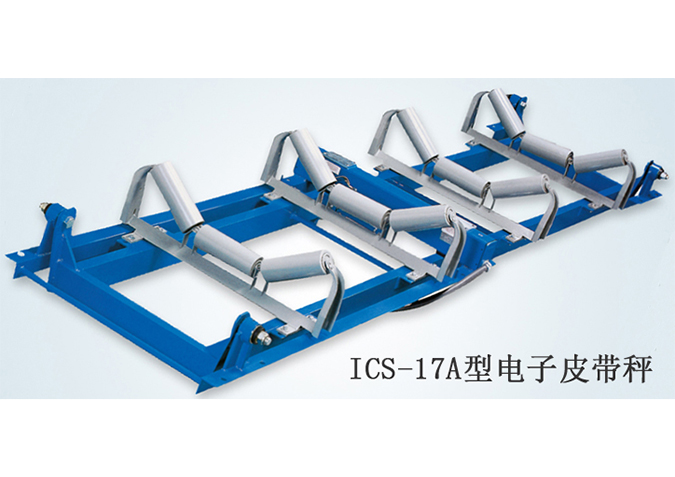

Simple structure, less force transfer links, simple and convenient installation;

Unique rectangular lever, good rigidity, invisible change;

Use rubber trunnion bearing, anti-corrosion, moisture-proof, anti-vibration;

Anti-lateral force, anti-horizontal force, effectively reduce the belt deviation and blanking off-load impact on the system accuracy;

The two weighing sensors are less affected by biased load, stable and high precision;

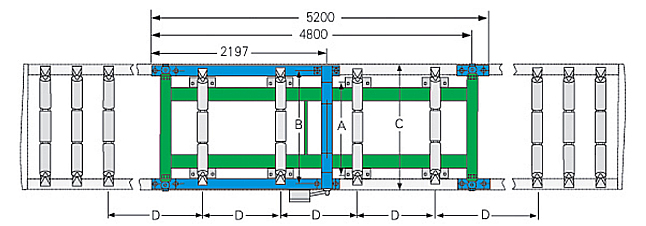

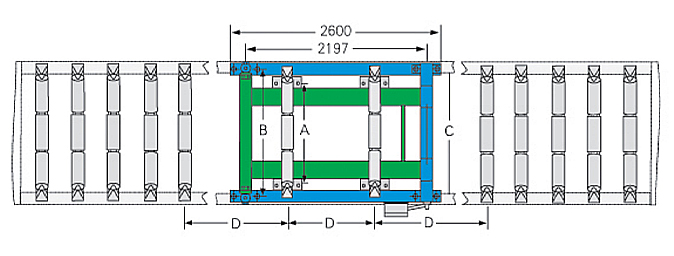

17A weighing area is wide, four groups of silver support to minimize the impact of belt on weighing;

Type 17B double support, short weighing area, suitable for short feeding distance belt conveyor.