PXL series dynamic cycle chain code verification device is installed above the electronic belt scale, located in the electronic belt scale body above the conveyor, the device can be in the belt conveyor no-load operation, automatically and smoothly placed on the belt above the belt scale body, dragged by the belt conveyor through the weighing section of the belt scale, closed-loop cycle chain code ring by the device mechanical transmission, By belt conveyor drag to achieve cyclic operation, to meet the simulation of the state of conveying materials, in order to complete the dynamic verification of electronic belt scale accuracy.

1. Product details

PXL series dynamic cycle chain code verification device is installed on the belt conveyor electronic belt scale for dynamic verification equipment, widely used in electric power, metallurgy, wharf, building materials, coal mines and other use of electronic belt to measure loose materials.

PXL series dynamic cyclic chain code verification device can realize the dynamic automatic verification of electronic belt scale accuracy, usually used to verify the accuracy of (0.5-2.0) between all kinds of electronic belt scale.

2.The main characteristics of the system

Chain code with belt synchronous operation, can be approximately breathless material delivery characteristics, and the actual operating situation of the similarity, so that the check more intuitive and reliable dynamic chain code put or lift are automatically operated by the electronic control system, according to user needs, can be set up remote output contact, for remote check room.

During the calibration process, the calibration instrument can display the calibration value, and the data can be transmitted to the centralized control room, so as to facilitate the user to check the accuracy of the current electronic belt scale.

Verification process is convenient and fast, high degree of automation, saving time and effort, accurate and reliable.

3. Working environment requirements

Ambient temperature: instrument -10~60C, mechanical -35~65C

Power supply: metering system and control loop

220VAC(+10% /-15%), 50Hz(2%)

Lift drive section

380VAC(+10%/-15%), 50Hz(+2%)

4.The working principle

PXL series dynamic cycle chain code verification device is installed above the electronic belt scale, located in the electronic belt scale body above the conveyor, the device can be in the belt conveyor no-load operation, automatically and smoothly placed on the belt above the belt scale body, dragged by the belt conveyor through the weighing section of the belt scale, closed-loop cycle chain code ring by the device mechanical transmission, By belt conveyor drag to achieve cyclic operation, to meet the simulation of the state of conveying materials, in order to complete the dynamic verification of electronic belt scale accuracy.

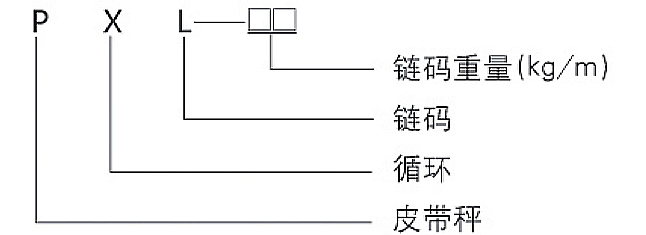

5.Product model

6. Equipment composition

Method 1: When belt scale and cycle chain code are one item, the instrument and speed sensor can be shared to achieve the purpose of reducing cost, improving reliability and convenient operation. At this time, cycle chain code is mainly composed of frame, standard chain code, upgrade system, electric control system, etc.

Mode two: When the cycle chain code is an independent item, it is mainly composed of frame, standard chain code, calibration display instrument, lifting system speed sensor, electric control system, etc.