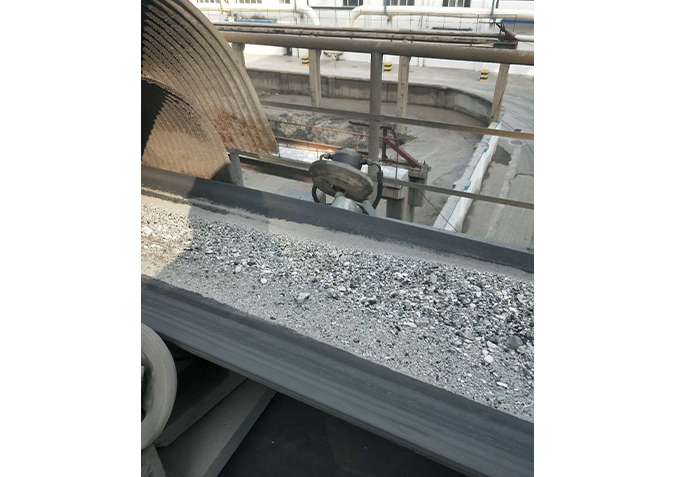

SHWY series belt conveyor on-line anti-deflection mechanism is mainly used in coal mine, metallurgical mine, power plant and other engineering roadway, belt conveyor passive hydraulic correction mechanism function. It is an updated product sold on the market at present. The SHWY series on-line passive hydraulic rectifying mechanism of belt realizes rectifying by rotating the detection wheel to drive the oil pump to supply oil to the rectifying cylinder, and by pulling the rectifying roller to give a reaction force to the belt, without external power source.

1.product use

SHWY series belt conveyor on-line anti-deflection mechanism is mainly used in coal mine, metallurgical mine, power plant and other engineering roadway, belt conveyor passive hydraulic correction mechanism function. It is an updated product sold on the market at present. The SHWY series on-line passive hydraulic rectifying mechanism of belt realizes rectifying by rotating the detection wheel to drive the oil pump to supply oil to the rectifying cylinder, and by pulling the rectifying roller to give a reaction force to the belt, without external power source.

Applicable conditions:

National standard belt conveyor

Loading transport tape:

Lower transport tape:

The tape width is 500 mm to 2000mm.

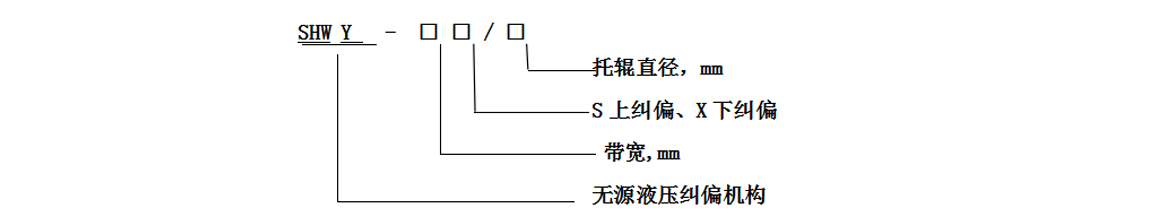

The representative meaning of the model

Example: Passive hydraulic rectifying mechanism for belt conveyor, applicable conveyor width 1200mm, deviation rectifying on S, idler diameter 133mm, model marked WY-1200S/133.

2. The working principle of the product

Principle of correcting deviation on tape

When the belt conveyor runs normally, the rectifying mechanism is in a static state. When the belt runs off course, friction is generated with the detecting wheel on one side. The detecting wheel drives the oil pump to rotate and supply oil to the cylinder at high speed, and the cylinder pulls the rectifying roller to give a force to the belt to realize rectifying.

Principle of lower belt correction

Same principle as above.

3.product performance characteristics

No external power source

The mechanism without external power source, through the belt deviation to achieve oil supply deviation correction.

Fully enclosed

The mechanism is completely closed, good dust effect, can avoid oil pollution, hydraulic oil loss is little.

Simple structure

Simple structure, convenient installation, low cost.

4.Installation technical requirements

Installation requirements

a) Before installation, check whether the frame is deformed and whether the fixed and rotating supports rotate flexibly.

b) Avoid damage to oil cylinder, oil pump, detection wheel and parts during handling.

c) During installation, the detection wheel should be offset by 10-15mm along the direction of the idler and separated by 50-60mm from the edge of the belt.

d) The connection of hydraulic hose must be installed as required to avoid wrong direction and unable to move.

e) After installation, carry out no-load test run. Observe if the movement is normal.

Drilling and installation

1) Check whether all parts and accessories are complete before sinking the well, and conduct surface debugging.

2) When sinking the well, it shall be transported in sections and assembled after being transported to the work place. Pay attention to the sequence of transportation to avoid inconvenience to the installation.

3) Pay attention to the connection position of the rubber hose during installation to avoid the wrong position and unable to move.

5. Operation methods and safety precautions

1) Maintenance personnel should regularly check and replace the detection wheel and fill with hydraulic oil;

2) Regularly check whether the fasteners of the drive wheel and oil pump are loose, especially the fastening of the connecting bolts on the frame;

3) Check regularly whether there is leakage in each part and deal with it in time.

6. Product labeling, packaging and storage

Product identification

Each product is fixed with a product label in an obvious position. The content of the signage includes:

1) Name of manufacturer;

2) Product name and model;

3) Main technical parameters;

4) Safety mark number;

5) Product delivery number;

6) Date of manufacture;

Product packaging

Product packaging shall comply with GB/T13384; Documents delivered with the product include:

a) Product operation manual;

b) Product qualification certificate;

c) Product packing list.

Storage and transportation of products

Products should be stored in ventilated and dry place, avoid rain, collision. Transport should be protected, strictly prohibited bump.

7.Quality Assurance

The user shall be responsible for free repair or replacement if the product is damaged or cannot work normally due to poor manufacturing quality within one year from the date of delivery or within six months of installation and use under the conditions of use and storage stipulated in the operation and maintenance manual.

8.Video presentation