The centralized batching system is a combination of computer technology, control technology, communication technology and graphic display technology. Its control function is perfect, display and operation are centralized, data processing is convenient, installation, maintenance is simple, the system is dry expansion. In the structure, the belt scale weighing instrument is cancelled, so that the signals of various sensors directly into the microcomputer interface module or PLC programmable controller, reduce the excessive connection points of the system equipment, achieve the purpose of centralized management, centralized control.

1. Product details

Sanhuai Heavy Industry centralized belt scale batching system, is based on the outstanding electronic belt scale system, according to the principle of computer centralized control and management and design. It ADAPTS to the material metering ratio of various bulk materials in the process of belt conveying, and becomes the ideal equipment for control in the production process of metallurgy, coking, chemical industry, sintering, pellet, mineral processing, building materials, light industry, cement, food, chemical fertilizer and other industries.

The centralized batching system is a combination of computer technology, control technology, communication technology and graphic display technology. Its control function is perfect, display and operation are centralized, data processing is convenient, installation, maintenance is simple, the system is dry expansion. In the structure, the belt scale weighing instrument is cancelled, so that the signals of various sensors directly into the microcomputer interface module or PLC programmable controller, reduce the excessive connection points of the system equipment, achieve the purpose of centralized management, centralized control.

2.The main characteristics of the system

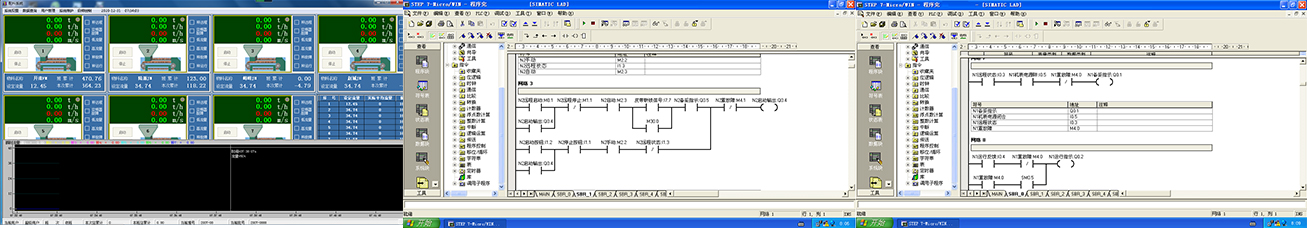

Through the computer switch in the data acquisition and industrial network communication technology, can real-time dynamic simulation of the whole batching process, dynamic picture realistic, friendly interface;

Support network data sharing, support 32-bit ODBC open data, network machine authorized by the network administrator can query the relevant data, support WINDOWSNT/NOVELL LAN, or through the modem dial-up Internet;

The system software supports WINDOWS multi-process and multi-threading mechanism, uses Visua-C ++6.0 programming, the best code optimization execution, fast speed and less system resources.

3.The working principle

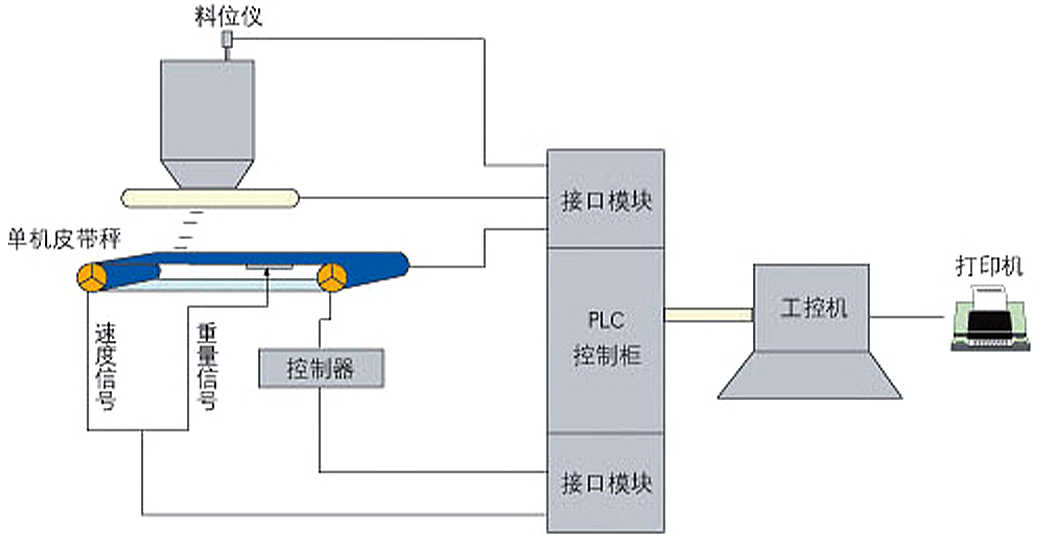

Disk feeder or other upper conveyor conveying material to the single belt scale, the single belt scale of the heavy star signal, speed signal through the interface module or PLC programmable controller, sent to the industrial computer, by the system software processing and display, at the same time, the use of PLC in the PID adjustment function and according to the user set PID parameters and ideal control value, Through PLC analog output module output 4-20mA current to the motor controller, and by its adjust the speed of the feeder so as to achieve the purpose of controlling the feeding amount.

4.Hardware distribution diagram of centralized batching system

5.Product parameters

Belt scale measurement error: ≤± 0.5% or ≤±1.0%

Batching system accuracy: ≤± 1.0% or ≤± 2.0%

Ambient temperature: 20C to 70C

System batching capacity range: 0~800 t/h

Material level measurement in the tip: ± 05% or ±1.0%

Power Supply: 380/220VAC, 50Hz

Current output: 0-20mA or 4-2omA is proportional to the flow rate of single belt scale

Communication network: RS-485/232