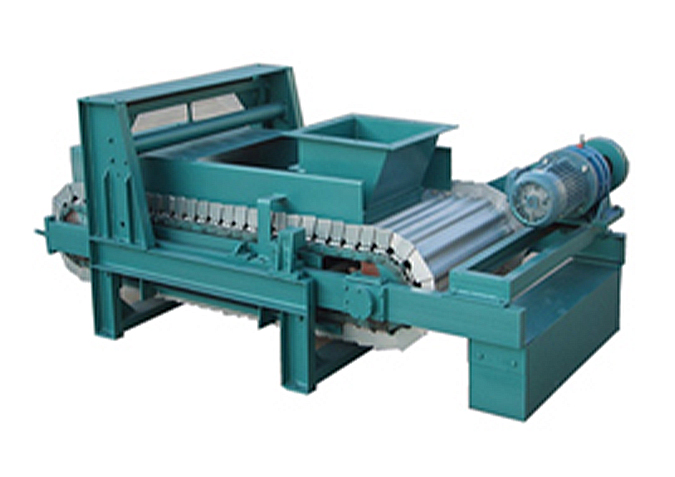

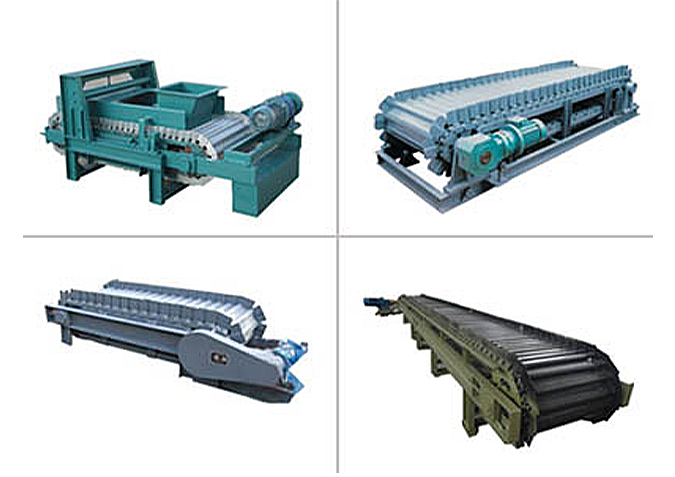

TDG-GL series chain plate scale is an automatic quantitative feeding or measuring device developed to solve the measurement and control of high temperature clinker in cement industry. It can be widely used in the measurement and feeding device of clinker out of kiln and high temperature clinker into mill in cement industry. In order to improve cement production, reduce heat consumption, and provide accurate measurement data for scientific management of kiln. It can also be used for continuous feeding measurement of materials with high humidity. TDG-GL high temperature chain plate scale adopts suspension installation mode, which highlights many advantages such as high measurement accuracy, reliable operation, simple maintenance, low maintenance and strong adaptability to environmental conditions.

1. Product details

TDG-GL series chain plate scale is an automatic quantitative feeding or measuring device developed to solve the measurement and control of high temperature clinker in cement industry. It can be widely used in the measurement and feeding device of clinker out of kiln and high temperature clinker into mill in cement industry. In order to improve cement production, reduce heat consumption, and provide accurate measurement data for scientific management of kiln. It can also be used for continuous feeding measurement of materials with high humidity. TDG-GL high temperature chain plate scale adopts suspension installation mode, which highlights many advantages such as high measurement accuracy, reliable operation, simple maintenance, low maintenance and strong adaptability to environmental conditions.

2.the main characteristics

The unique L-shaped transport plate is made of wear-resistant steel plate by die stamping molding, compact structure, smooth operation, minimal noise, and the conical baffle on both sides can effectively prevent the leakage of materials;

Conveying mechanism adopts large pitch cast sprocket and single curved plate roller chain P=100) after special heat treatment, high temperature resistance, wear resistance and no deviation phenomenon in the conveying process;

Drag mechanism supporting BW series cycloidal pin wheel reducer, smooth transmission, low noise, low vibration, dust resistance;

The unique weak magnetic gear speed measuring device and high temperature resistant load sensor make the weighing and measuring speed signal accurate and stable.

4.Product details

Static measurement error: ≤0.5%

Dynamic cumulative error (equivalent) : ≤2%(in use)

Control accuracy: better than 2% Measurement range :1-200t/h

Zero stability: better than 0.007%Cmax

Weighing signal nonlinearity: ≤0.5%

Speed measurement signal: 40 pulses/revolution

Four-stage three-phase AC induction motor: 1.5kw, 2.2kw

High temperature resistance range: <350C

Measuring clinker specification: granular, block, diameter is not greater than 80mm to ensure uniform discharge shall be subject to

Sensor: The accuracy of weighing sensor and velocity sensor is better than 0.1%. The weighing sensor has overload protection, and the overload coefficient is 150%